Full Range Measurement and Why It Matters

Posted by Appion on Jul 5th 2023

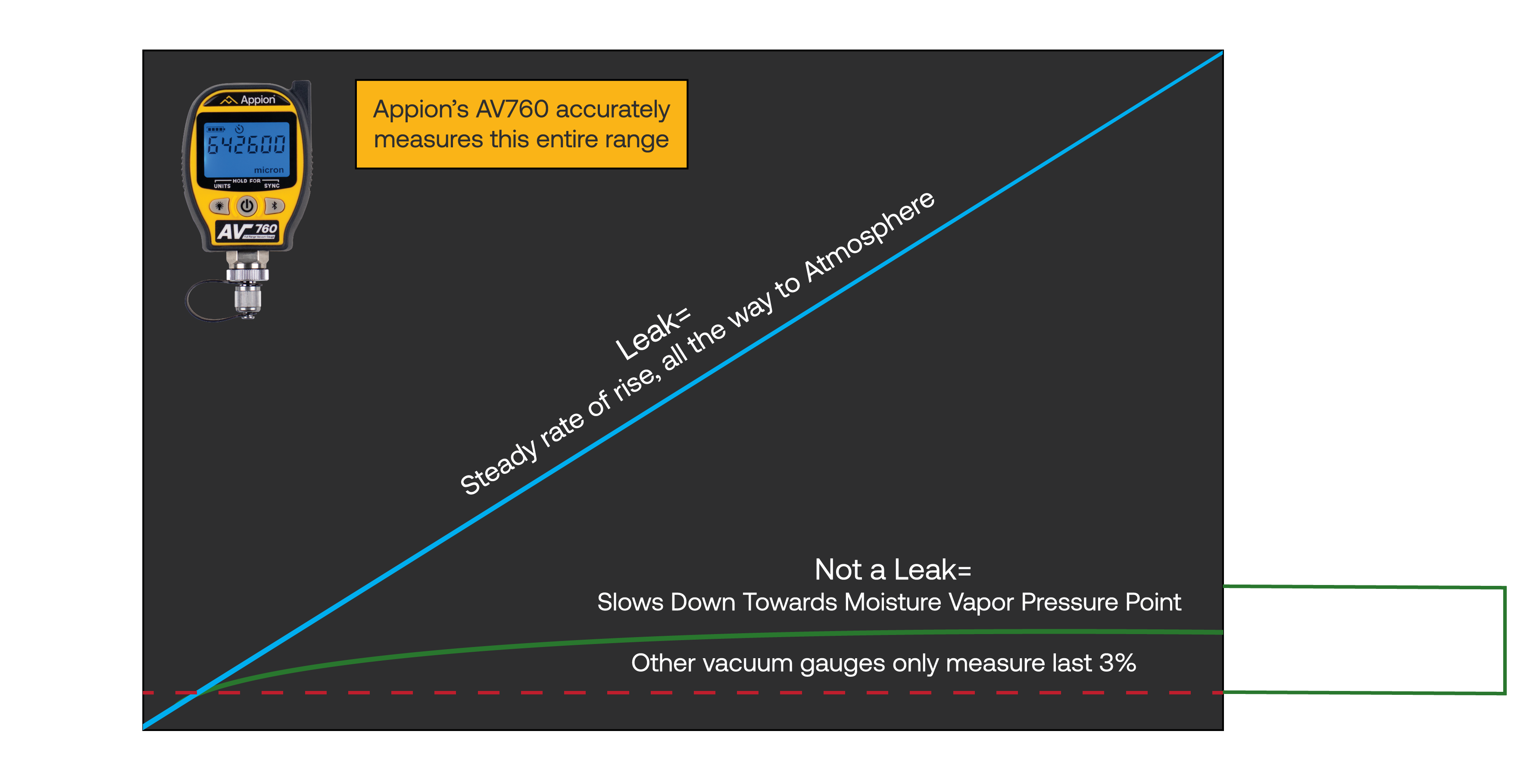

It’s not something that may seem very important, but the ability for a vacuum gauge to measure the entire evacuation is invaluable to a technician. ‘Full Range’ simply means a digital vacuum gauge reads from atmosphere (760,000 microns, or 14.7psi at sea level) all the way down to 1 micron. Full Range measurement allows for a glimpse of what’s happening within the system at every stage of evacuation.

An example of why this is so important happens during the “blank off” test. Have you ever seen a system hold pressure but leak under vacuum? Using a Full Range gauge can help with troubleshooting. Typical AC/R vacuum gauges begin measuring at 25,000 microns, which is only the last 3% of the whole evacuation process. Since the vapor pressure of moisture can exceed 50,000 microns on a hot day, a “blank off” test on a system with excess moisture can easily rise beyond the reach of a typical vacuum gauge’s range.

Without Full Range measurement, any moisture trapped in the system can easily be mistaken for a leak. When performing a “blank off” test with full range measurement, the rate of rise can show the difference between contaminants and moisture in the system or a leak. A leak will quickly and steadily rise all the way to the atmosphere. If the system has moisture trapped in it, the rate of rise will slow down around the vapor pressure point.

Visualizing Full Range Measurement

*Appion's AV760 accurately measures this entire range*

Accuracy

System evacuation can be a very complicated task. With variables ranging from system tonnage to levels of contamination, there are a lot of things all happening simultaneously. If all of these variables are also being measured by an analog gauge) or a digital gauge with a small measurable range), the uncertainties begin to multiply.

Analog gauges provide low resolution and low accuracy. Atmosphere at sea level is 760,000 microns. Now divide the compound range of an analog gauge by 76, this would only be a 10,000 micron resolution. Considering the width of the needle to the divided compound range, the needle could be anywhere from ≈10,000 microns to 50,000 microns ‘wide’. These issues of lack of resolution make it near impossible to accurately measure 500 microns on an analog gauge. 500 microns is the industry standard level at which all moisture and contaminants are considered to be removed from the system. With such a poor resolution the analog gauge could stop moving when the dehydration stage of the evacuation is just beginning.

Digital vacuum gauges are the solution for poor resolution. Many digital vacuum gauges have an average resolution of ≈1 microns when reading below 1000 microns (depending on the manufacturers specifications). With a resolution this fine, accuracy and range of measurement becomes even more important.

Accuracy is how close the gauge’s reading is to what is actually happening in the system. As with resolution, a digital vacuum gauges accuracy is determined from the manufacturer’s specifications. Most accuracy ratings are given as a ± % of reading format, a lower number corresponds to greater accuracy. A low ± % reading isn’t the only aspect of accuracy that is important. Reliability and repeatability are crucial.

Full Range Solution

Appion’s AV760 addresses all these needs. With a 1 micron resolution below 500 microns and a 5 micron resolution below 2000 microns. With a resolution this fine, it’s easy to accurately see when the system is at or below 500 microns. The AV760 is the only AC/R vacuum gauge with ±5% NIST-traceable accuracy with 10-point certification and full range measurement. Every AV760 is tested against a lab gauge that is calibrated to a NIST( National Institute of Standards and Testing) gauge before shipment. With high resolution, high accuracy, and full range the AV760 gives you the confidence to know that the job is done right.

Gauge Placement

For a system to be adequately dehydrated, a deep vacuum must be achieved throughout the entire system, not just the point where the vacuum pump is connected. Unlike pressure, vacuum will not quickly equalize across all points of the system. For the most accurate reading of vacuum depth throughout the system, it is recommended that you attach a vacuum gauge at an access port on the system that is farthest from the Vacuum Pump. It is possible, for example, to have one end of the system evacuated to 1,000 microns, while another end - far from the vacuum pump - can still be at 10,000 microns.

Additional Materials