Fast Recovery Series: Fast Recovery in Application

Sep 27th 2024

Fast Recovery Series: Fast Recovery in Application

Introduction

With a better understanding of refrigerants and the effective restrictions gathered throughout this series of blog posts, we can apply this knowledge to practical applications in the field. Until this point, many topics have revolved around two-port direct refrigerant recovery. While this type of recovery helps us lay the foundation for the fundamentals of fast recovery, direct refrigerant recovery is not the only method available. Other methods include deploying other techniques or add-on equipment, such as push-pull recovery and daisy chain recovery, or even leveraging the system's capabilities to transfer refrigerant to built-in refrigerant storage. With this broader perspective, we will now explore the different types of refrigerant recovery, examining their respective strengths and weaknesses to provide a more comprehensive understanding of the options available.

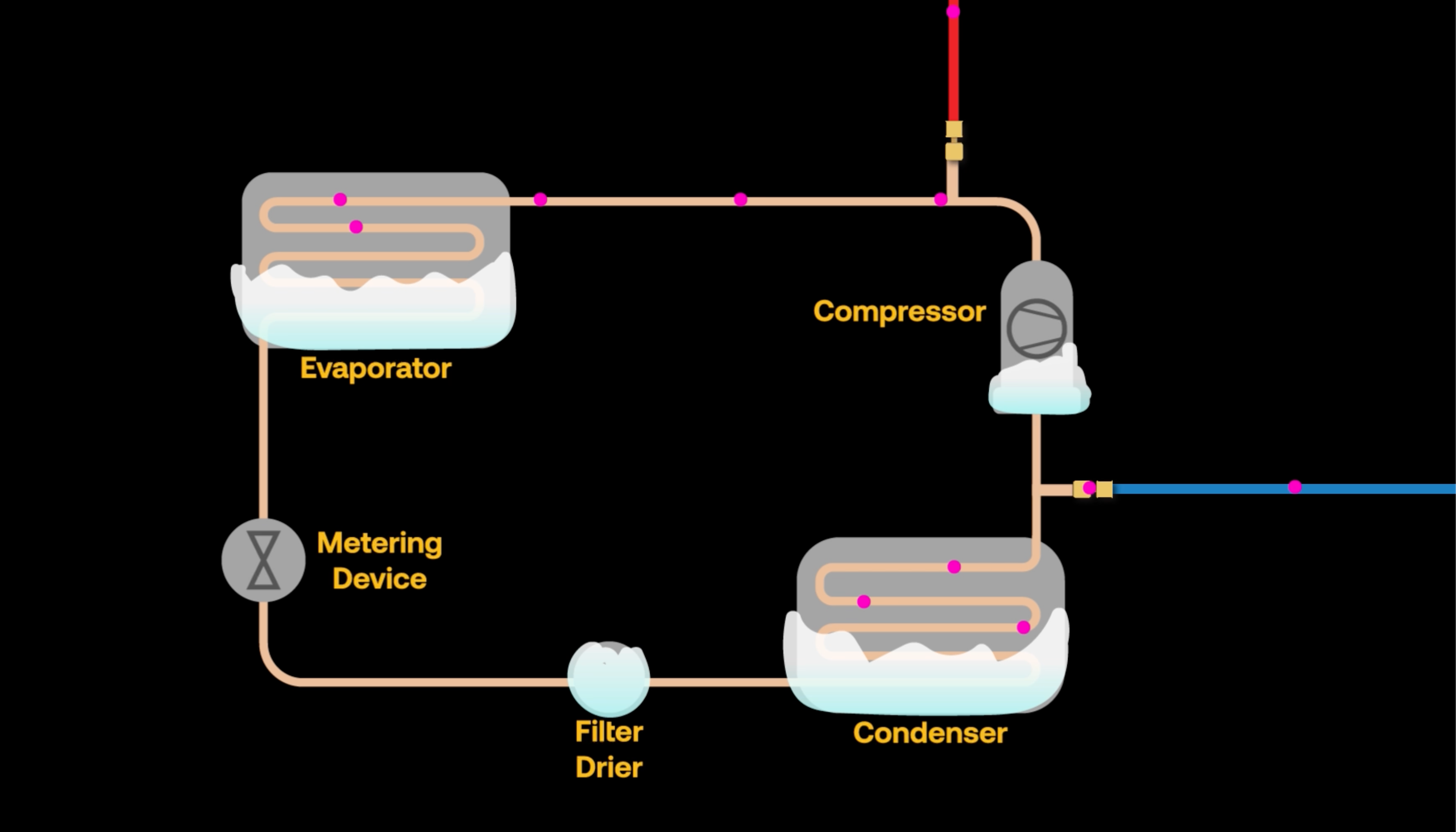

Two-Port Direct Recovery

Two-port direct refrigerant recovery is the most commonly deployed refrigerant recovery method. While valued for its ease of setup, it does have some limitations. The most common drawback to this form of recovery is heat buildup at the recovery cylinder. This heat buildup can often be eliminated by deploying the full-flow techniques discussed in a previous blog post. However, other techniques or add-on tools should be utilized in some environments with high ambient temperatures.

Two-Port Recovery Setup Example

Heat Mitigation Techniques: Flipping the Cylinder

One of the easiest add-on techniques is flipping the recovery cylinder. While this technique can only sometimes be used due to limitations with recovery cylinder design and weight, it is often a great technique to utilize when applicable. Flipping the cylinder allows liquid refrigerant to fill from the bottom up but through the less restrictive vapor port. Once the vapor refrigerant portion of recovery begins, the liquid refrigerant that is already recovered will aid in transferring heat that the incoming vapor refrigerant may be carrying. The recovery cylinder can then reject this heat in various ways. The most common way is using the recovery machine to pull air over the recovery cylinder to aid heat dissipation. When recovery is nearly finished, or the recovery cylinder is ready to be swapped out for another cylinder due to capacity limitations, the cylinder can be flipped upright. With the cylinder upright, any remaining liquid refrigerant in the output hose can migrate to the recovery cylinder. Clearing the output hose of liquid refrigerant will reduce unnecessary refrigerant loss during the disconnection of the hose after recovery has been stopped.

Flipped cylinder

Heat Mitigation Techniques: Ice Bath or Freezer

In some applications, flipping the cylinder is not an option due to limitations with recovery cylinder design and weight or does not provide adequate heat transfer due to extreme ambient temperatures. Using external cooling accessories can save you valuable time when faced with these issues. An extremely effective way to reject heat during direct refrigerant recovery is to submerge the recovery cylinder in an ice bath. This technique chills the recovery cylinder and allows for maximum heat dissipation. Since the recovery cylinder is now at a low temperature, it has an increased ability for heat rejection, reducing the cylinder pressure to below the recovery machine's output pressure. Still, this technique has limitations regarding recovery cylinder size since it may be hard to find a large container to hold the cylinder and ice. When a recovery cylinder size is of concern, pre-chilling the cylinder before recovery is a great option when a walk-in freezer or cold room is accessible.

Cylinder in an ice bucket

Cylinder in a walk-in freezer

Heat Mitigation Techniques: Subcooler

If neither of these options is available, another external cooling accessory that can be deployed is a refrigerant subcooler. When submerged in ice, a subcooler allows heat rejection to occur after the recovery machine and before the recovery cylinder. Subcoolers, while effective with larger recovery cylinders, still require a purge process at the end of recovery. This is because refrigerants will always migrate to low-temperature low-pressure areas, and the lowest-temperature area is located before the recovery cylinder.

Subcooler in a recovery setup

Push-Pull Recovery

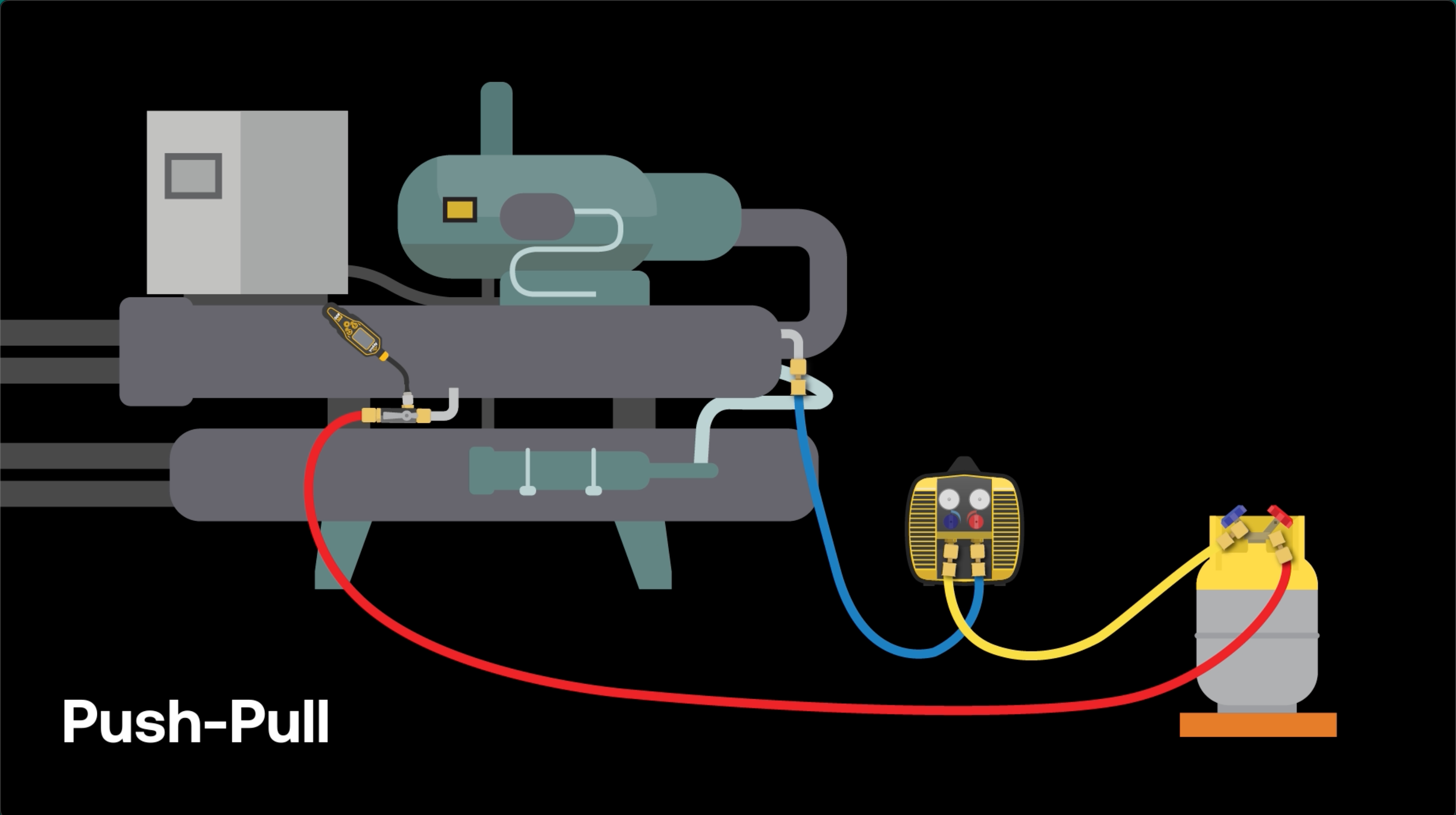

These stated techniques are fantastic options for dealing with direct refrigerant recovery and can be used on many different system sizes and types. However, direct refrigerant recovery may not be the best option for dealing with systems that allow access to large amounts of liquid refrigerant. Push-pull recovery can be deployed when working on systems with a liquid receiver tank, flooded evaporator, or condenser. This method, while typically a little more complex to set up, can be beneficial as it allows the technician to quickly move large amounts of liquid.

In push-pull recovery, the recovery machine will be set up in a manner that pulls refrigerant vapors from the recovery cylinder and pushes refrigerant vapor into the system. The refrigerant vapors then push the liquid refrigerant in the system into the recovery cylinder, where the recovery machine can repeat the cycle of pulling the vapor refrigerant from the recovery cylinder. This recovery method is extremely efficient when moving large amounts of liquid refrigerant because the closed-loop recovery setup creates the pressure differentials needed to move liquid refrigerant continuously without excessive heat buildup. The drawback to this closed-loop setup is that you must stop the process and switch to a direct refrigerant recovery setup to remove any remaining vapor.

Push-Pull recovery example

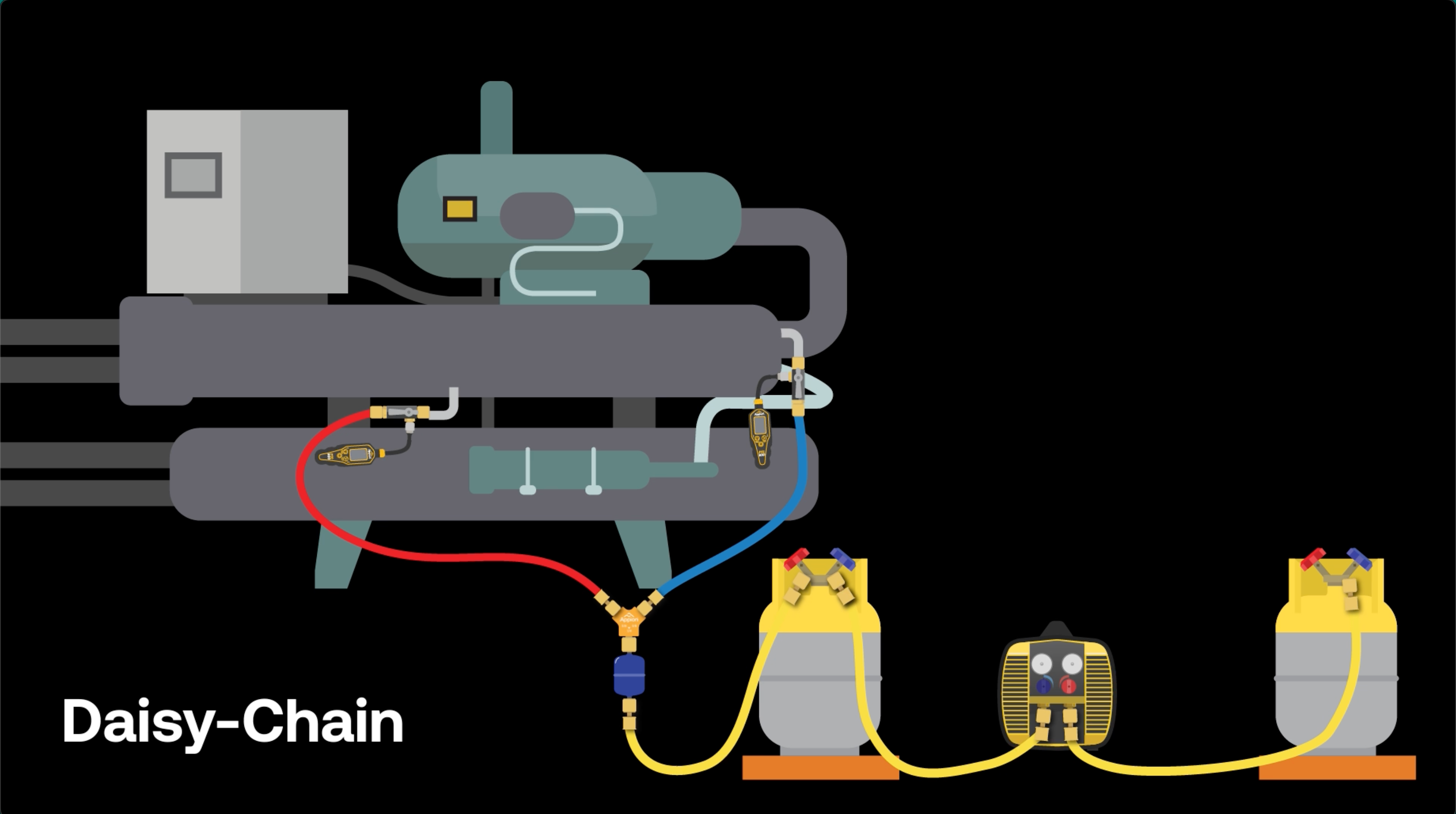

Daisy-Chain Recovery

Since push-pull has to be stopped and reverted to a direct refrigerant recovery setup, sometimes daisy-chain recovery is preferred on larger systems. Daisy-chain recovery is a blend between push-pull and direct refrigerant recovery. With this recovery method, liquid and vapor refrigerant is pulled from the system and drawn into the liquid port of the first recovery cylinder. The recovery machine then pulls vapor refrigerants from the first cylinder and pumps those vapors into a second recovery cylinder through the vapor port. While this recovery method doesn't require the process to be stopped, if the cylinders are sized appropriately, the second recovery cylinder can fall victim to excessive heat buildup. Because of this, the external cooling accessories or techniques we discussed earlier in this blog post may need to be utilized to dissipate this heat.

Dasiy-Chain recovery example

Built-In Recovery Systems

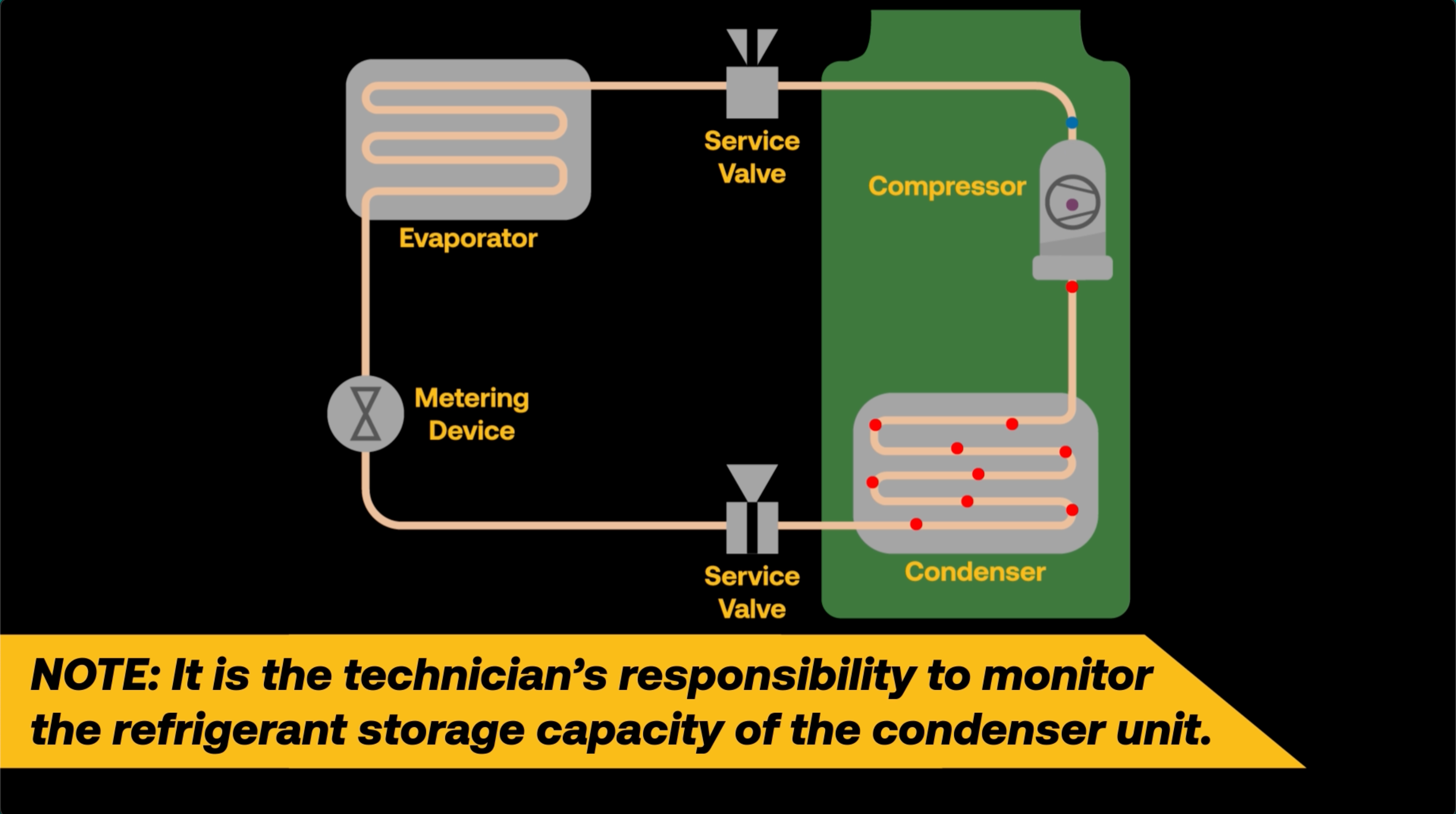

In some instances, auxiliary recovery equipment may not be required at all. Modern VRF systems are equipped with a pump-down mode. This mode utilizes the system's compressor to recover the refrigerant charge and store it in the condensing unit. This is particularly helpful for systems requiring repair to components beyond the condensing unit.

In some specialized applications, large chilling and refrigeration systems have built-in refrigerant storage and recovery pumps to allow the refrigerant recovery to take place within the system that is being serviced. Systems of this type typically utilize a blend of programmable controllers, manually operated valves, and fixed pipes. These components operate the built-in recovery pump and monitor critical measurements such as pressure and saturation temperature, as well as direct refrigerant and water around the system as needed. Systems of this design do not require auxiliary recovery-specific tools and are often designed to accommodate fast refrigerant flow during these onboard recovery processes. However, this is with the mindset that the fixed components within the system do not fail. If a critical component that controls these processes fails, auxiliary recovery tools and full-flow practices learned throughout this series will be of great benefit to a job of this size.

Built-in recovery system example

Frosting & Static Buildup

It's important to note that recovering refrigerant at such a high speed can lend itself to the frosting of components in static buildup. Frosting on components in a system will occur when the refrigerant is in a liquid form or trapped in the compressor oil. As the liquid or trapped refrigerant boils off, these components will begin to frost. The release of this refrigerant can be aided by applying heat. When accessible, running fans and sump heaters during recovery will also help boil off any trapped or liquid refrigerant. In the case of chillers and water-sourced condensers, it is important to circulate water through evaporators and condensers during recovery. Once recovery is complete, stopping chilled water flow will prevent condensation. During repair, this must be assessed on a job-by-job basis.

Frost built up on system components

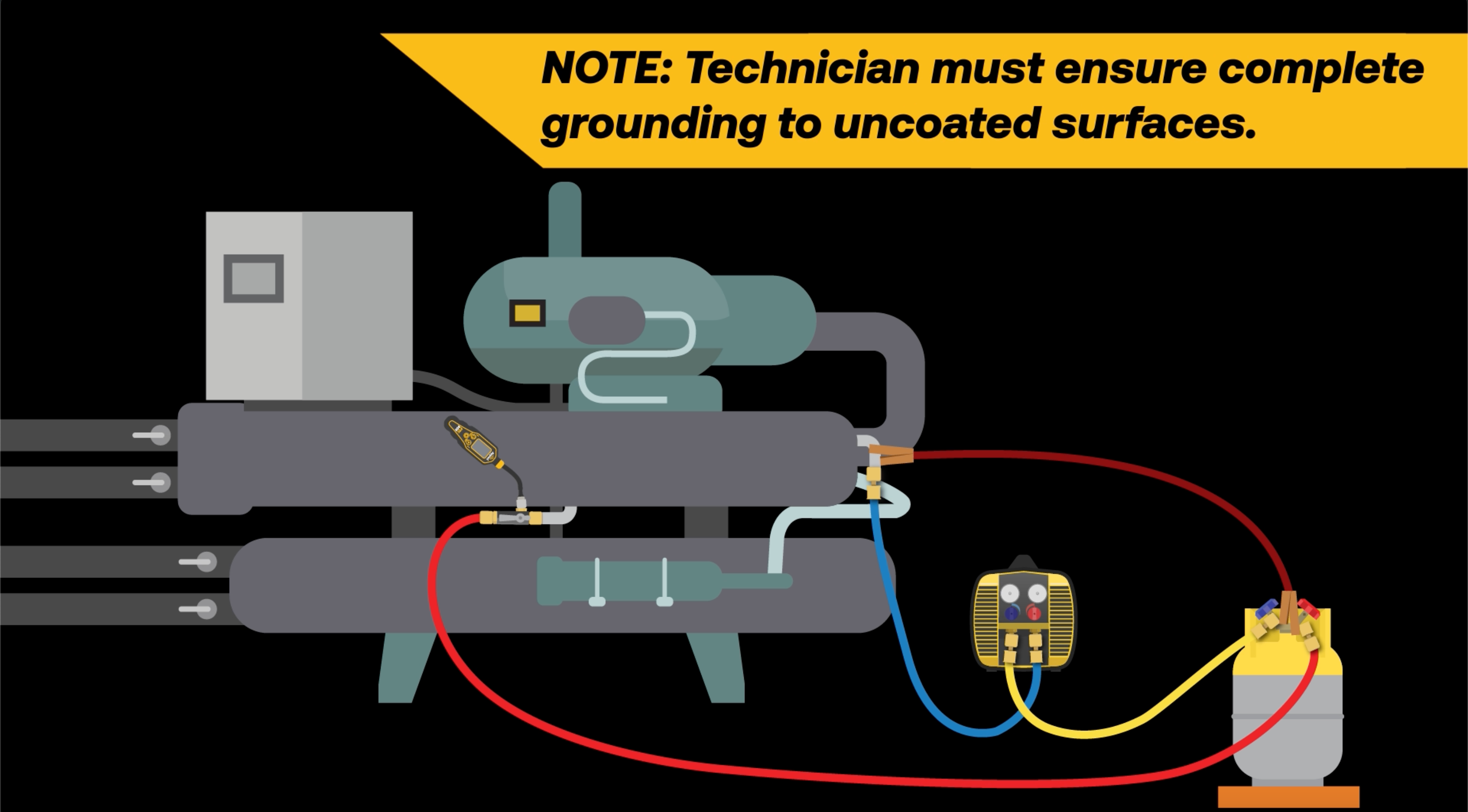

The Importance of Grounding

Grounding your recovery setup is often an overlooked process. Ensuring each component in the setup is grounded properly is a must for static charge mitigation. This includes but is not limited to, making sure the system hoses, recovery machine, and even the recovery cylinder are properly grounded. When moving refrigerant at such a high speed, a transfer of electrons between the refrigerant and hose lining can occur. This often leads to a static charge building in the recovery cylinder. Attaching a grounding cable between the cylinder and a known good ground will allow this charge to dissipate before building to a state that could jeopardize your safety and the safety of those around you.

Grounded recovery setup example

Conclusion

Armed with this greater knowledge, it is imperative to remember the HVAC/R industry is constantly evolving with complex systems that can vary greatly depending on the application in which the system is designed to work. Even the approach to refrigerant recovery on the same system can vary depending on failure modes. As an HVAC/R technician, it is your responsibility to be aware of all conditions and utilize proper diagnostic procedures to devise a recovery plan that best suits the situation you are dealing with. It is also your responsibility to comprehend and utilize industry best practices while staying up-to-date with rules and regulations, allowing you to perform safe and efficient refrigerant recovery.

Watch our Fast Recovery Series on YouTube: