Fast Recovery Series: Overview

Posted by Appion on Sep 17th 2024

Fast Recovery Series: Overview

Introduction

At some point during the life cycle of an AC system, the refrigerant charge will need to be removed. In these Fast Recovery Series blog posts, we will review proper safety measures and techniques to increase the speed of a safe, quality recovery. Whether it's to service, repair, or replace the system, the refrigerant should be removed with proper care and precaution. There are many machines and tools to make this process easy. However, thorough knowledge of refrigerants and refrigerant recovery will ensure fast, quality service. it's important to understand why we recover.

History of Refrigerant

First, it helps to understand where refrigerants started and how they've changed over the years. By the 1970s, CFC refrigerants were being used by virtually every commercial space in the country and many other countries worldwide. Unfortunately, what was once considered harmless turned out to be the opposite. In the 70s, researchers found that chlorofluorocarbons were carried high into the stratosphere, where the molecular compound would degrade from the sun's ultraviolet radiation. The chlorine atoms would separate and break down the ozone molecules, turning them into oxygen. The problem increases when you factor in that the said reaction doesn't consume the chlorine, so this ozone-to-oxygen cycle repeats for years. This ozone layer degradation exposes the Earth to the adverse effects of ultraviolet radiation.

After the ban on CFC refrigerant production, most modern systems use refrigerants based on hydrochlorofluorocarbon or hydrocarbon. Although they are safer regarding ozone depletion, recent research has shown that they still fall victim to the environmental impact of fluorine, which is now regulated as Global Warming Potential, or GWP. Many countries are already phasing out HCFC’s and HFC's use and production, some with goals as soon as 2030. These environmental impacts of ozone depletion and greenhouse gas effects caused by uncaptured refrigerants are the main driving factors for why we recover refrigerants in the first place. Another reason for recovery is the unnecessary cost of replacing reusable refrigerant that has been removed for system repair. These cost savings are already in impetus worldwide with systems that use a large amount of refrigerant but will be compounded as the continued phase down of HFCs occurs.

Chlorine and oxygen molecules deplete the ozone

Refrigerant Toxicity and Flammability Classification

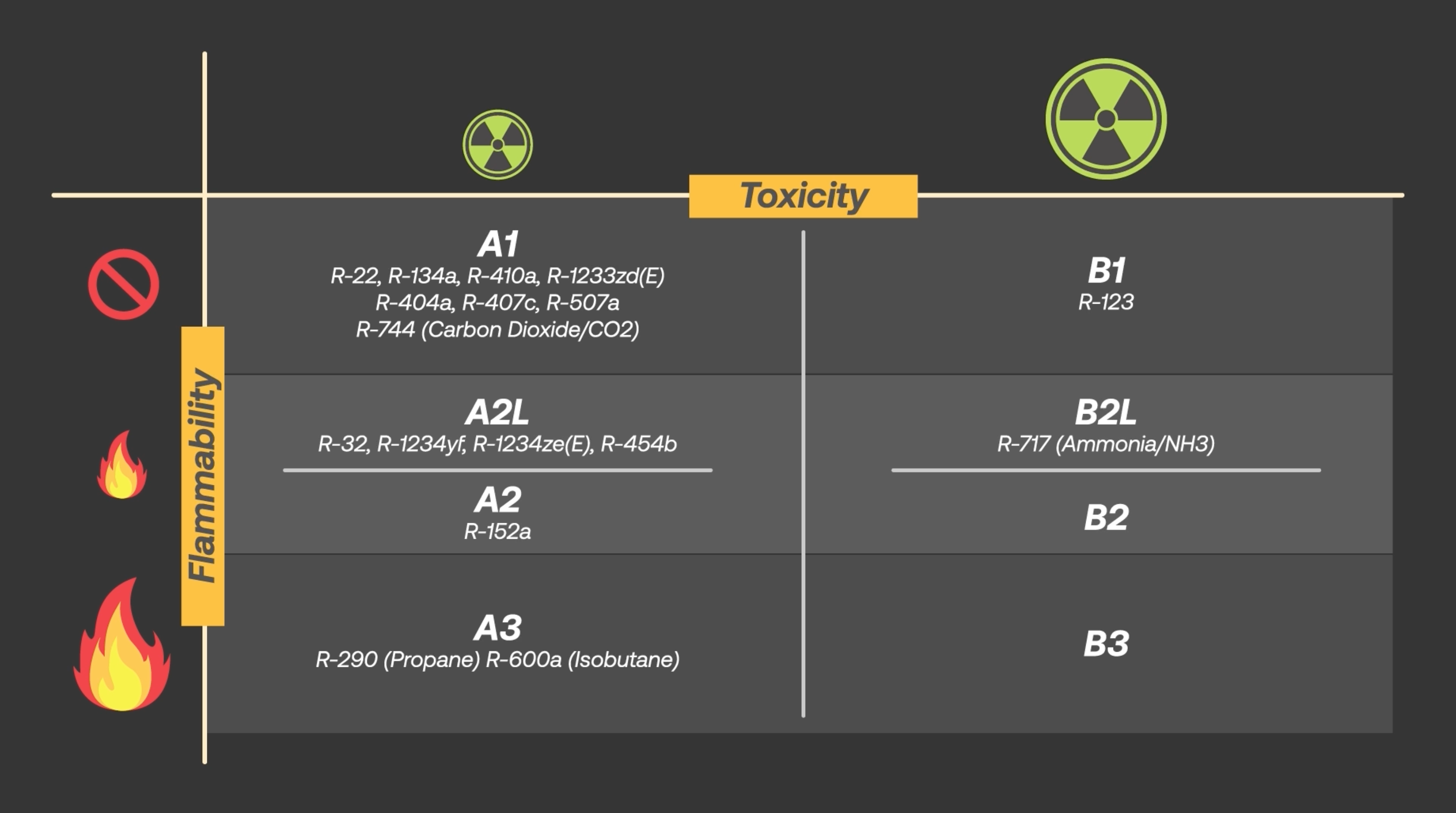

Along with environmental dangers, refrigerants are also harmful to living beings. There are different levels of flammability and toxicity that can cause asphyxiation and/or physical harm. The American Society of Heating Refrigerating and Air-Conditioning Engineering, known as ASHRAE, classifies refrigerants by hazard based on toxicity and flammability through Standard 34. Toxicity is signified with the letter A or B, while flammability is rated numerically (1, 2L, 2 or 3). Simply put, Class 3 refrigerants are highly flammable, Class 2 refrigerants are less flammable, Class 2L refrigerants are mildly flammable, and Class 1 refrigerants are considered to show no flame propagation. Understanding these differences will help you choose the best equipment for each system and job.

Flammability vs. Toxicity Chart

Zeotropic & Azeotropic Refrigerant

With these differences, it's important to never mix refrigerants. There are some special cases when it comes to manufacturer blended refrigerants. Zeotropic and azeotropic refrigerants are two types of successfully blended refrigerants. A zeotropic blend is a mixture of two or more refrigerants with different boiling points. An example of a zeotropic blend is R407C. On the other hand, an azeotropic blend is a mixture of two or more refrigerants with the same boiling point, meaning they will condense and evaporate together. An example of an azeotropic blend is R507.

The advantage of azeotropic blends is that you won't have to worry about refrigerant glide and fractionation like you would with zeotropic blends. Simply put, glide is the difference in boiling point between the most volatile component and least volatile component in a refrigerant blend. This leads us to fractionation. When a zeotropic refrigerant blend is in the cylinder, the different components will boil off at different temperatures. Due to this and other different properties, including density, there may be different amounts of each refrigerant vapor in the space above the liquid. To ensure that the system receives the proper blend, it is recommended to charge it with the liquid blend by flashing it into the system to avoid damaging the compressor with liquid refrigerant.

Zeotropic vs. azeotropic refrigerant blend boiling points

Refrigerant Within a System

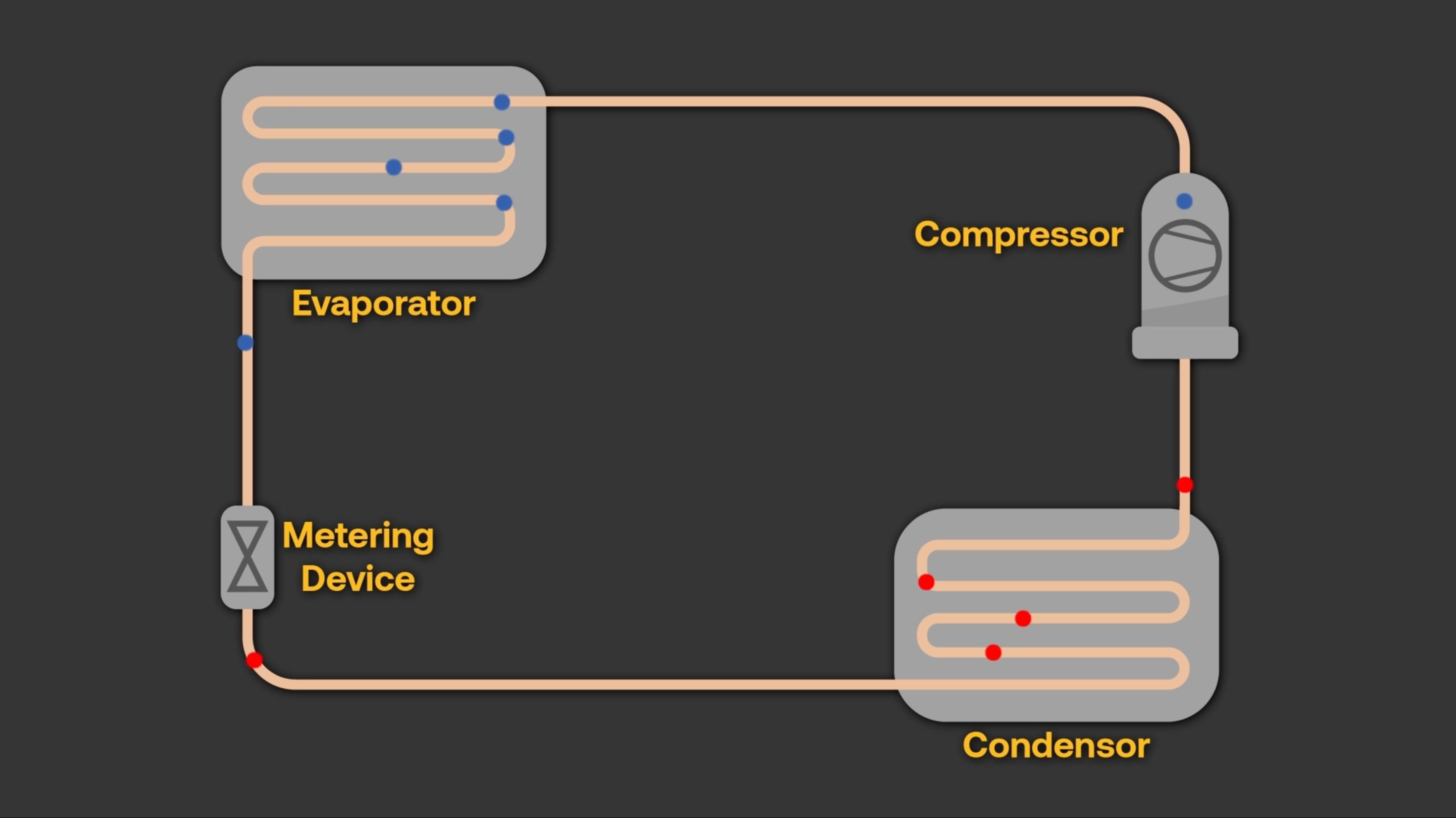

Regardless of the application, refrigerant type, or components of an AC/R system, the basic refrigeration principles are the same. Refrigerant absorbs heat in the evaporator, turning the low-pressure liquid refrigerant into a vapor. The compressor is then used to draw the refrigerant from the low side, compress it, and discharge it into what has now become the high side. This raises the temperature of the vapor refrigerant above the ambient temperature. The heat of the refrigerant can now be rejected through the condenser, turning the refrigerant back into a high-pressure liquid. This high-pressure liquid is passed through a refrigerant control device that causes a pressure drop, changing the refrigerant to a low-pressure, low-temperature liquid and starting the cycle again.

Refrigerant movement and temperature/pressure throughout a system

Conclusion

Now that we understand how an AC/R system works, it can help us understand why refrigerant recovery can be such a challenge. Refrigerants are specifically selected for their unique ability to gain pressure and temperature when compressed. These attributes of refrigerant make the process of recovery even more difficult, and as such the process needs to be rethought. Next, we will discuss key points to working with recovery cylinders. Read more here.

Check out our Fast Recovery Series on Youtube: