Fast Recovery Series: Full Flow Basics

Sep 27th 2024

Fast Evacuation Series: Full Flow Basics

Introduction

In this blog post, we will review equipment performance and the fundamentals of a full flow recovery setup. An important part of fast recovery is the ability to trust the accuracy of your tools and equipment during the recovery process.

Test Your Tools For Leaks

Before performing any recovery service, you should always test your tools to ensure they work correctly and have no leaks. Checking your tools can be as simple as visual inspections or more complex, specific baseline performance testing to make sure the tool being used is ready for the task at hand. An understanding of how to perform these tests to ensure your tools are working correctly is necessary to ensure a safe and fast recovery. Purging the entire recovery setup is essential to any recovery job and applies to all recovery methods. Purging the hoses and recovery machine prevents non-condensables, contaminants, such as moisture and oil from other refrigerants, and air from mixing with the recovered refrigerant. This is especially important when recovering A2L or mildly flammable refrigerant since an air mixture can create an ignitable concentration. It also ensures that any refrigerant being reused or returned for recycling is in its purest state.

Always inspect and test your tools before recovery

Liquid & Vapor Recovery

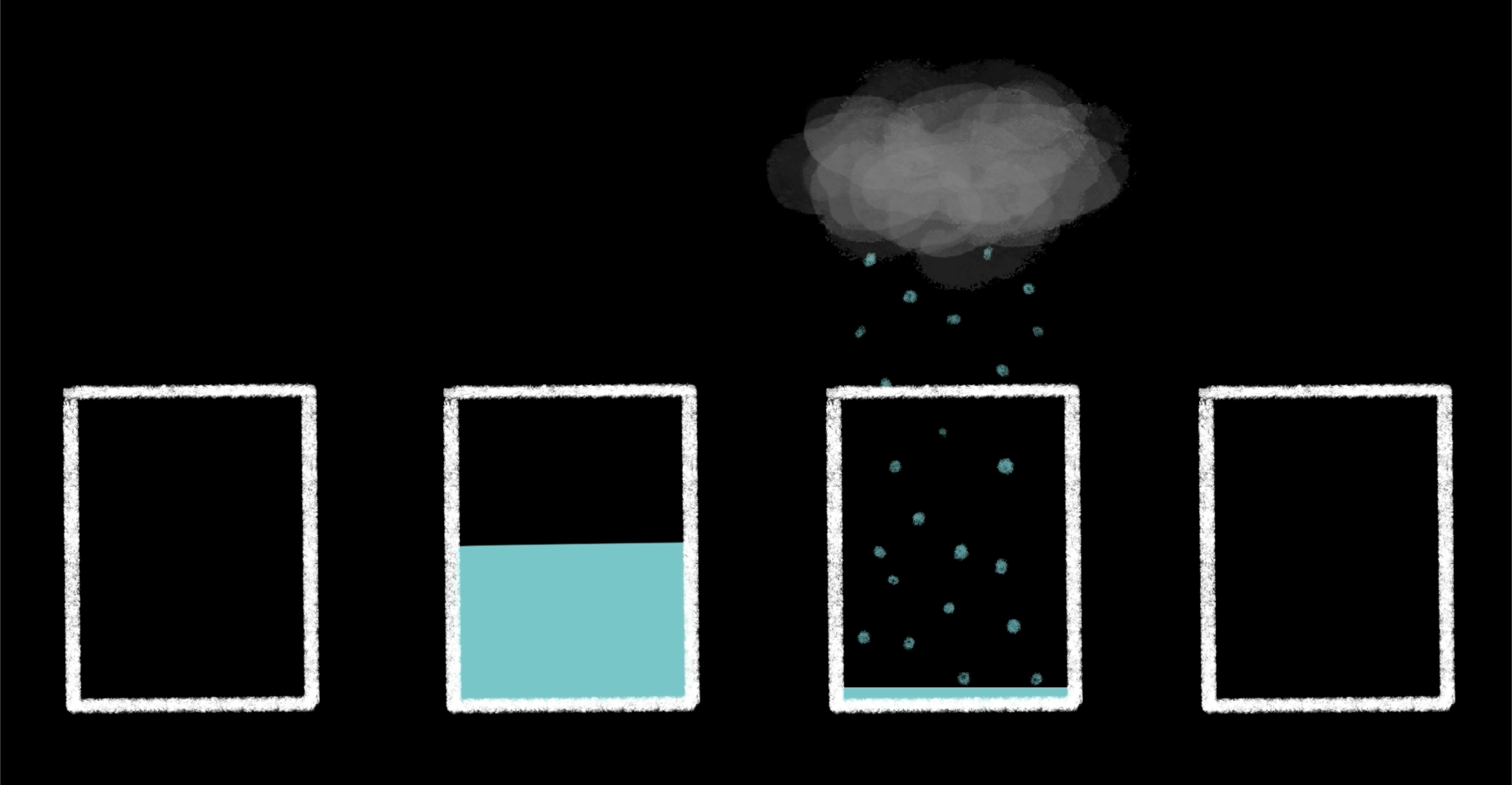

When setting up for a fast recovery, the goal is to achieve full flow. Before we get into the specific components of a full flow setup, we must first understand the difference between liquid and vapor recovery. Liquid refrigerant can be up to 300 times denser than vapor. Because of this, it's recommended that liquid refrigerant be recovered whenever possible. A helpful way to understand why moving liquid refrigerant is faster than moving vapor refrigerant due to liquid density can be visualized using two pots. One pot is full of water, while the other is empty, and we must transfer the water from one pot to the other. You have two options to transfer the water to the second pot. You could simply pour the water directly from one pot into the other, only vaporizing and recondensing any remaining residual water. Alternatively, you could vaporize the water and then recondense it into the other pot. The first method is significantly quicker. This is because the bulk of the water is moved in its liquid phase, which requires far less energy than changing its phase.

In contrast, the second method is time-consuming and energy-intensive, as it involves waiting for the water to evaporate and then recondensing, which is a more complex and energy-demanding process. This analogy directly applies to refrigerant recovery since moving refrigerant in its liquid form is more efficient. Similar to pouring water from one pot to another and then converting it to vapor and back to liquid. However, moving liquid refrigerants can present challenges for some recovery machines.

Option 1 vs. Option 2

Recovery Machines: Oil-less and Refrigerant-Isolated Crankcases

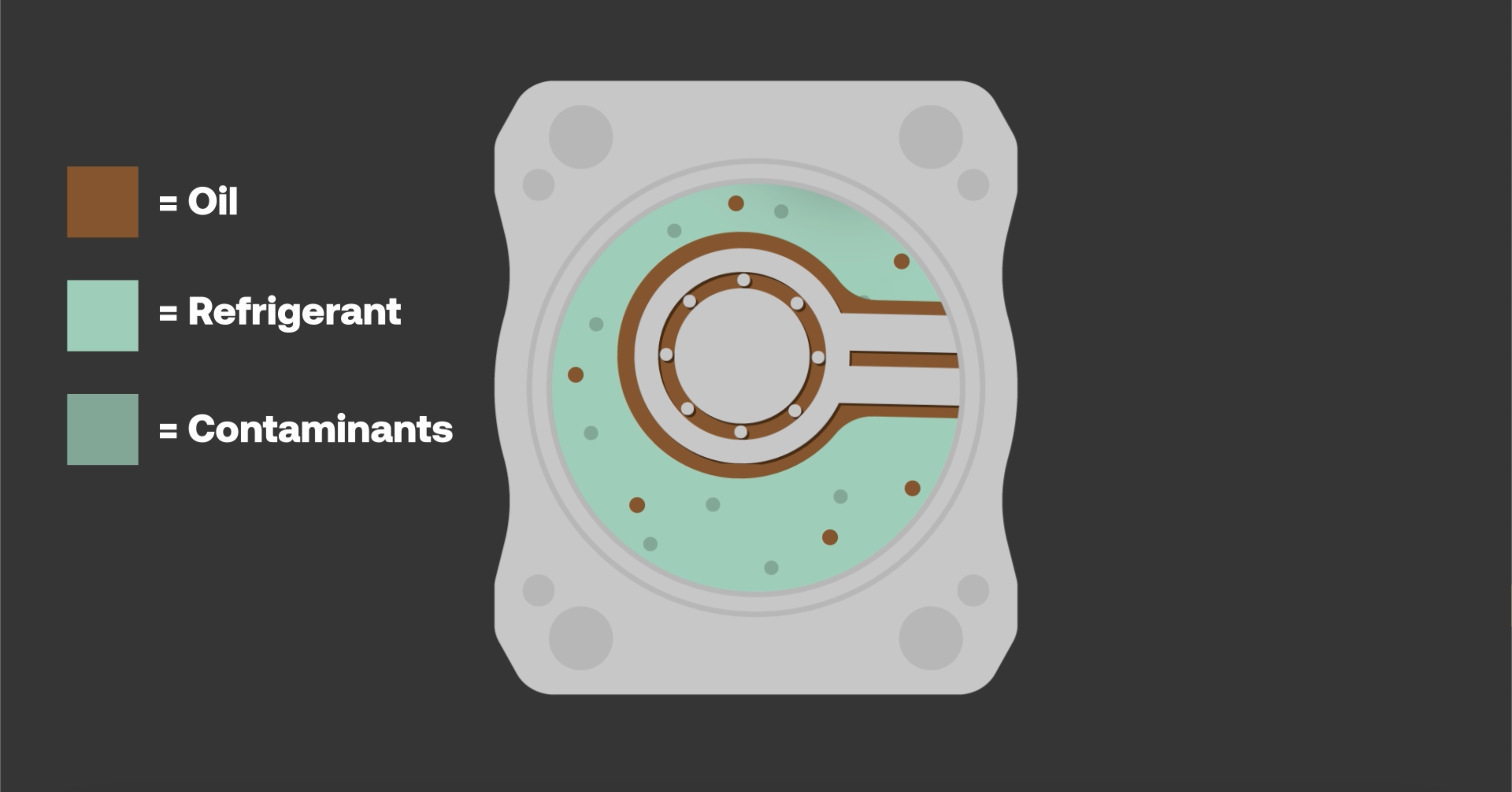

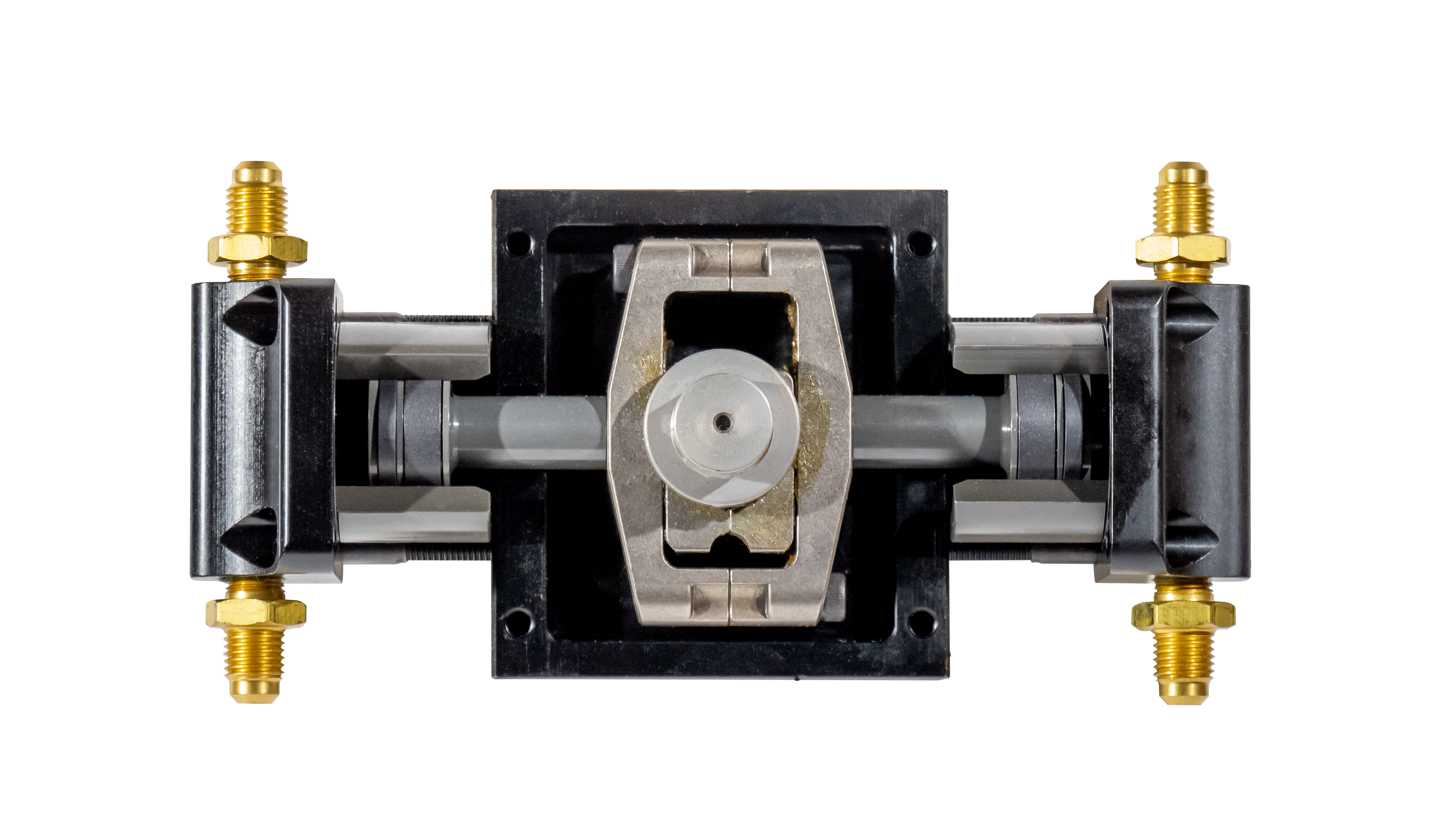

Most recovery machines cannot recover liquid refrigerant due to the risk of internal component damage. A common workaround that some recovery machine manufacturers incorporate is a throttling knob to control the amount of liquid that is entering the compressor. While throttling refrigerant does help avoid liquid hammering and potential damage, it comes at the cost of restricting the refrigerant flow, ultimately slowing the recovery process. In the 1990s, recovery machine manufacturers started to develop machines with oil-less compressors. These machines don't have an oil sump but still require oil to lubricate rotating components. Some oil-less compressor recovery machines utilize a refrigerant-flooded crankcase design to get the oil needed for lubrication. This design relies on system compressor oil trapped in the recovered refrigerant to enter the crankcase for lubrication. The downside to this design is the potential to flush the compressor bearings of any lubricating oils when pumping virgin refrigerant. This stripping of lubrication can lead to early failure of the bearings and possible cross-contamination.

Lastly, recovery machines of this design need a purge function to remove refrigerant trapped inside the flooded crankcase at the end of recovery. This adds an extra step to maintain EPA compliance and avoid cross-contamination. You need a machine that can handle liquid refrigerants to have the fastest recovery times. A recovery machine with a permanently lubricated, refrigerant-isolated crankcase, like the G5Twin, negates the risks of pumping liquid. Without the reliance on compressor oil, these recovery machines can pump liquid and virgin refrigerant without issue. This allows for a full-flow setup, increasing recovery speeds and utility on the job site.

Oil-less Crankcase

Oil-less Crankcase

G5Twin Permanently-Lubricated Refrigerant-Isolated Crankcase

The Importance of Filter Dryers

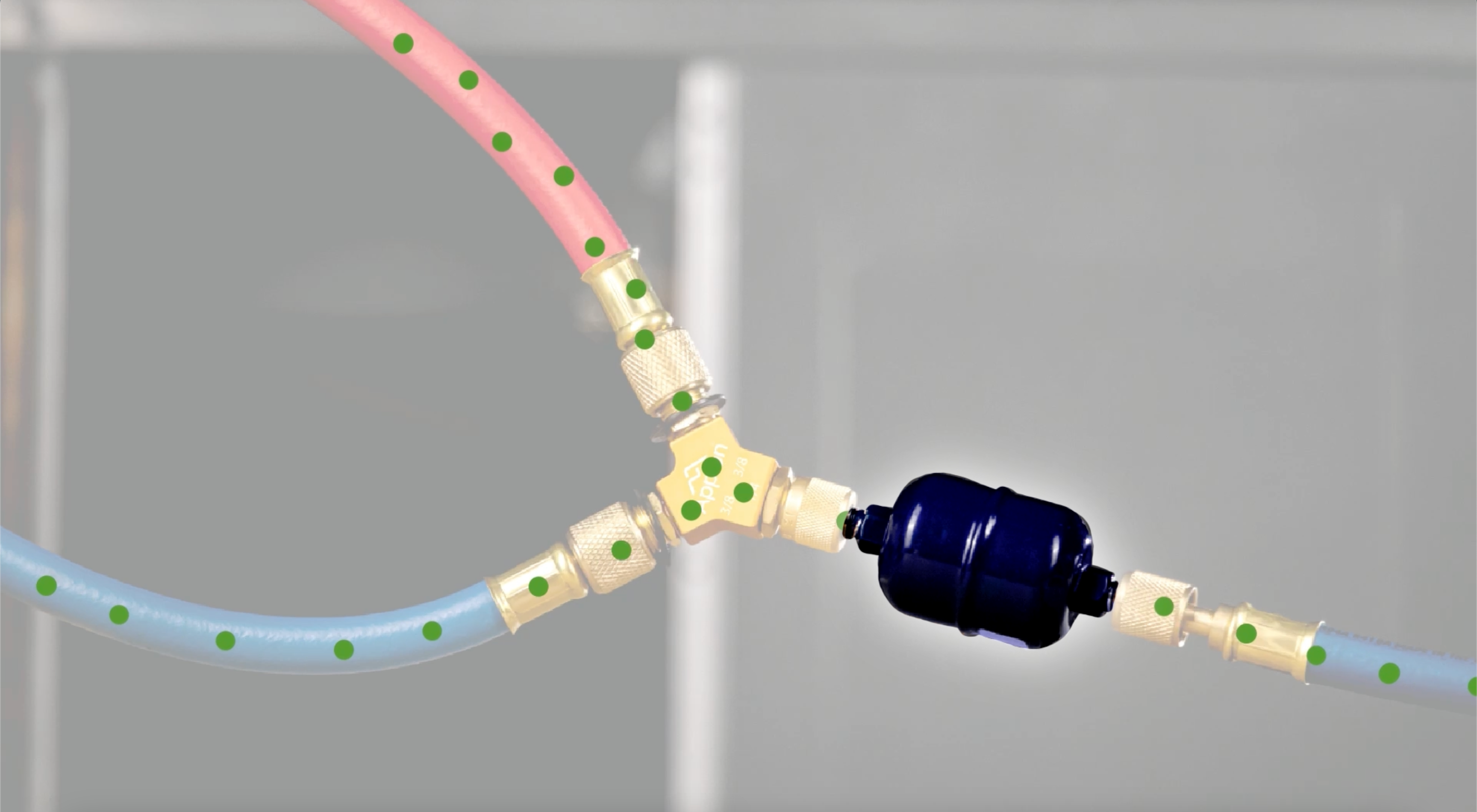

Another important element of your refrigerant recovery setup is the filter dryer. Its primary role is to safeguard the recovery machine against debris and contaminants rather than cleaning the refrigerant itself. This is especially important while servicing systems that

are wet have undergone a compressor burnout, or are otherwise contaminated. Failing to replace the filter dryer can lead to painfully slow recovery times and refrigerant cross-contamination. Therefore, as a best practice, it is highly recommended to always use a filter dryer and regularly replace it between jobs to ensure the longevity and efficient operation of your recovery machine.

Filter dryer utilized in full flow setup

Also, it's important to ensure refrigerant cannot be trapped by solenoid valves, expansion valves, and branch boxes. These components can be controlled by magnets or onboard system controls to ensure full flow and full refrigerant recovery.

Refrigerant trapped by solenoid valve

Conclusion

Now that you understand proper equipment performance and basic full flow principles, we can review advanced full-flow practices deployed during the recovery process. Read more here.

Watch our Fast Recovery Series on YouTube: